WL Series - For Wide mouth and large volume containers.

For Large Volume, Oval & Flat Bottles and Wide-Neck Jars

PET Stretch Blow Molding Machine

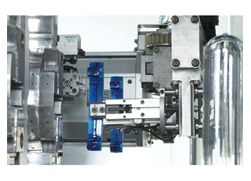

CPSB-W/L Series (Large Capacity) RHSB

W/L SERIES

PET Stretch Blow Molding Machines

Wide Mouth and Large Capacity Series PET Twin Shaft Reheat Blowing Machine

Wide Mouth Feeding

Wide Mouth Bottle & Wide-Neck Jar Blow Molding Machine (PET RHSB)

CHUMPOWER W/L Series

CHUMPOWER W/L Series is cost-effective, modular design for easy maintenance, compact structure for saving space, and can make Oval, off center, Petaloid, Square, Flat, Round bottles, Jars and Wide mouth containers.

Suitable for various markets to produce different bottles, such as Mineral water, Carbonated beverages, Edible oil, Alcoholic drinks, CSD, Non-perishable food, Cosmetics, Medicine bottles, Detergent, Tennis bottles. Unique robotic arm design increases preform in-feeding stability. Includes highly reliable hydraulic clamping design and double robotic arms for speedy preform loading. Unique auto-infeed system for preforms with different neck diameters.

Special heating layout structure to minimize space and energy consumption.

Bottle Preform Feeding

Unique robotic design increases the stability of the preform and uses Double-injection mechanical jaws to accelerate preform load time.

Universal loading system for preforms of different calibers (within a limited range) using Automatic alignment.

Compact Heater System on all models

Examples of Large Bottles

Typical Feeding System

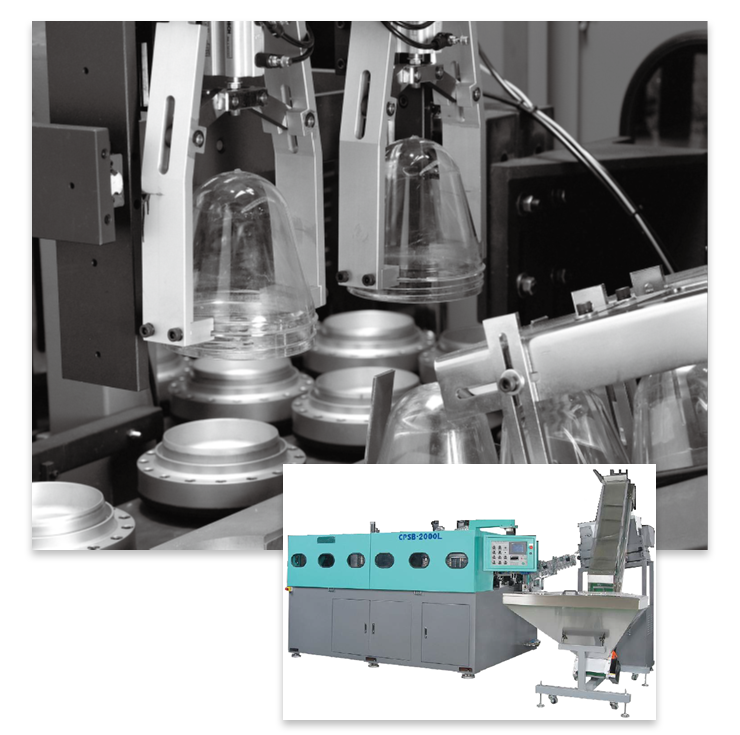

Typical Blow Mold

Clamp Mechanism

Important Optional Accessories

- Robotic arm system for pre-insertion of handle in oil bottles

- Side-heater system for oval & flat bottle preforms (preferential heating).

- Positioning device for preform orientation.

- Air recycling system for lower energy consumption

- Oil bottle handle front implant system

- Blowing bottle positioning device

- Blowing gas recovery system

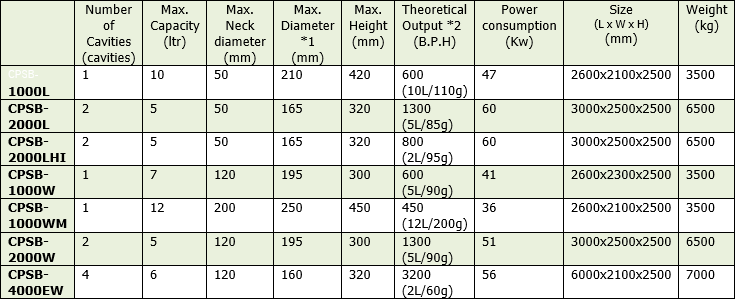

Engineering Specification Chart

- Specifications are subject to change without notice

- The actual output depends on the preform quality and bottle shape. The final capacity depends on the preform and bottle type.